Principle

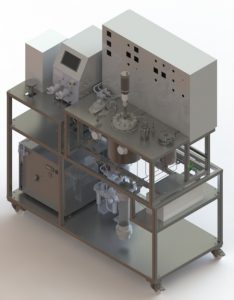

Multi-process laboratory skid: FAME (Fluid Assisted Micro-Encapsulation) and SAS (Supercritical AntiSolvent). This skid allows atomization thanks to the properties of supercritical CO2. It is mainly composed of :

– Two high pressure autoclaves

– A CO2 pump

– A co-solvent pump

– A compressor

– A chiller

– A hot bath

– A spillway

Principle and operation

SAS (Supercritical AntiSolvent) : It consists in solubilizing the material in an organic solvent, then contacting the solution thus formed with a supercritical fluid (CO2 in general). This phenomenon will lead to the precipitation or recrystallization of the material, which will then be in the form of a fine powder. The supercritical fluid appears as an anti-solvent. This process is called SAS, for Supercritical Anti-Solvent.

FAME (Fluid Assisted Micro Encapsulation) : It consists in solubilizing supercritical CO2 in a material until saturation. This mixture is then depressurized and expanded.