Principle:

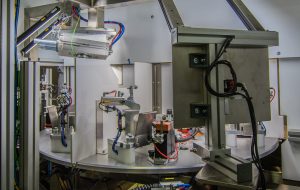

Cell equipped with a 4 positions indexing plate:

– POSITION 1 : Manual loading/unloading station

1. Manual loading of a mirror on the rotary table and connection of its beam to the cell (as well as the camera cable according to the version of the mirror)

2. Product presence control

3. Clamping produced via automatic clamps

4. Camera presence control or shell without hole

5. Manual unloading of controlled products NOK

– POSITION 2 : Checkpoint

Allows you to perform several controls on the rearview mirror.

1. Heater consumption control

2. Camera consumption control

3. Power consumption and vision control Mirror travel position left/right

4. Control consumption and vision control mirror travel position Sky/Earth

5. Consumption control and luminescence vision control BSW

6. Consumption control and vision position control Electric folding

7. Control consumption and vision control luminescence blinker

All controls are modulable via the HMI: assignment to position 2 or position 3

– POSITION 3 : Checkpoint + fold down

Allows multiple controls on the rear view mirror as well as manual folding

1. Probe presence check (only straight products)

2. TPE sole presence control

3. Sole presence control THERMO

4. Heater consumption control

5. Camera consumption control

6. Power consumption and vision control Mirror travel position left/right

7. Control consumption and vision control mirror travel position Sky / Earth

8. Consumption control and luminescence vision control BSW

9. Consumption control and vision position control Electric folding

10. Control consumption and vision control luminescence blinker

11. Folding (for manual version) and folding force measurement

All controls are modulable via the HMI: assignment to position 2 or position 3

– POSITION 4 : Unloading and labeling station

1. Robot grasping the rear-view mirror

2. Unlocking the connectors and unlocking the rear view mirror via the locks

3. Positioning of the rear-view mirror at the control of the shutter by the robot

If NOK control: Deposit of the product in a waste bin by the robot

4. Labeling of the part

5. Checking the label after it has been applied.

If NOK control: Deposit of the product in a waste bin by the robot.

6. The robot places the product on a conveyor belt to exit the cell.