Chemical Processing

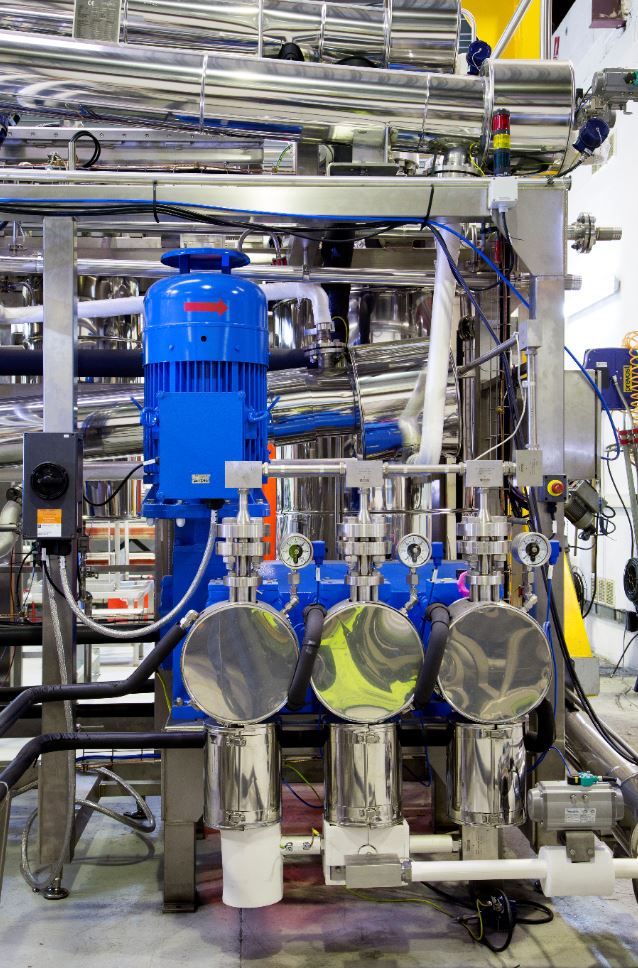

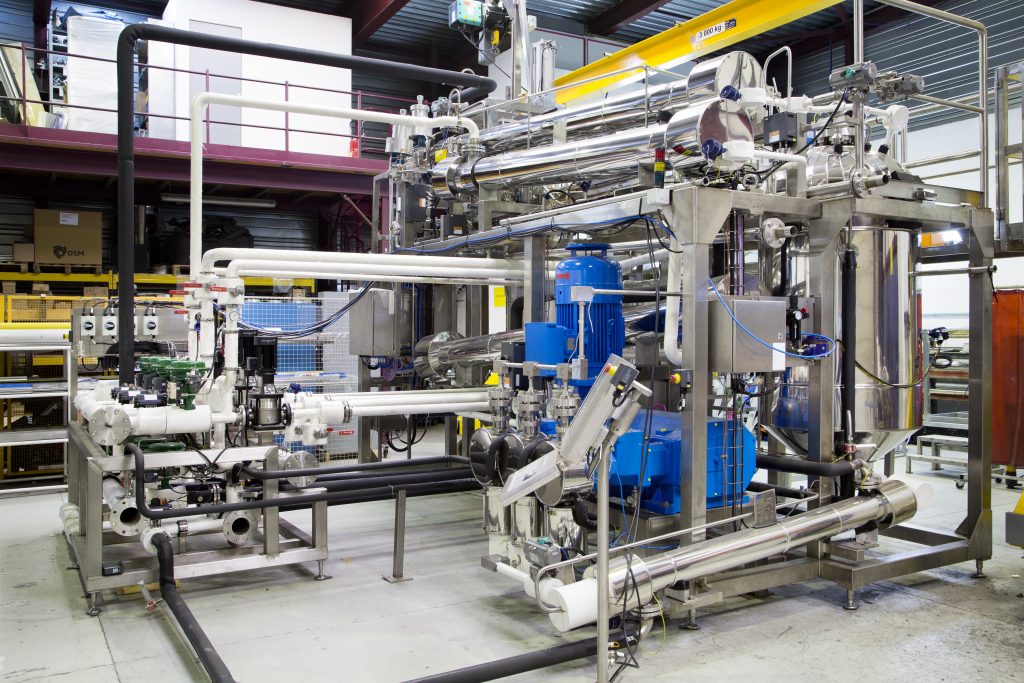

Manufacturer of industrial equipments for new extraction processes using supercritical carbon dioxide and subcritical water.

Some examples of the processes developed at ER INGENIERIE :

- High pressure extraction with different fluids (CO2, H2O, Alcohols, Ethers, Alkanes…)

- Liquid materials fractionation (Omega-3)

- API encapsulation by jet atomization

- Production of nanometric powders for galenic purpose

- Impregnation of materials (tissues dying, chemical reactions on organic materials)

- Contaminants elimination (pesticides, plastics recycling)

- VOCs treatments

New : our standard range of extraction skid

An extraction project ?

Request a quote and get one of our supercritical fluids extraction equipment.

From Lab to industrial size units, our skids are designed and realized according to cGMP to guarantee the quality of your products.

Know how & Applications

EQUIPEMENTS DEDICATED TO NATURAL PRODUCTS TREATMENT

There is a wide range of possibilities for the high-pressure treatment of natural products. We can extract solids like plants for perfume industry (lavender, roses, jasmine…) and for food industry (vitamins, antioxidants, aromas…) as well as fractionation of liquid raw materials (unsaturated fatty acids separation) and elimination of dangerous materials like pesticides and allergens. According to clients request ER INGENIERIE is able to provide initial feasibility study or design and manufacture an equipment or do the complete process (from initial idea to the machine implementation).

- Laboratory studies (trials)

- High pressure extractions of plants

- High pressure extractions of see products (algae, fishes, krill)

- Pesticides elimination treatment

- Fungicides impregnation treatments

- Extraction of omegas 3, 6 and 9

- EPA / DHA fractionation

- Polyphenols extraction

- Flavonoids extraction

- Extraction of essential oils (terpene derivatives)

- Vitamins extraction (tocopherol)

- Alkaloids extraction (nicotine, caffeine)

SEE OUR AUTOMATIC EQUIPMENTS

Cosmetic industry is continuously progressing for more than 40 years. Still today, this sector is constantly researching new products and processes so as to enrich their consumer product line.

It’s in this context that ER INGENIERIE offers a large range of equipments dedicated to these applications.

- Essential oils extractions

- Emulsion, body oils manufacturing

- Natural dyes extractions

- Improved penetration of active products with adapted formulation

- Perfumery

- Soap factory

- Solar products, cream

- Organic products (ECOCERT)

DEDICATED EQUIPMENTS FOR PHARMACEUTICAL INDUSTRY

The techniques of extraction, pulverization, micro-encapsulation by means of high pressure fluids lead to new possibilities for drug manufacturing (galenic).

Complementary to classical processes like coacervation, spray-drying, evaporation, fluidized bed, the processes based on supercritical fluids use permit to achieve better performances in terms of biodisponibility of the active product. Same remark for APIs encapsulation.

- APIs extraction from plants (carbon dioxide or water or…)

- Galenic – Slow release pharmaceutical forms

- Biodisponibility control

- cGMP equipments manufacturing

- Chemical reactions in supercritical media

- Viruses and bacteria inactivation

- Therapeutic cannabis (CBD)

- Phyto-ingredients

- Atomization with high pressure fluids

- Encapsulation

- Delipidation (vaccines)

- Cleaning and degreasing of bones implants

- Viruses and bacteria inactivation with CO2

- Bioresorbable tissues manufacturing (surgery) and functionalized (surface treatment)

DEDICATED EQUIPMENTS FOR CHEMISTRY / NON BIO MATERIALS

High pressure applications can be used in many different industrial domains like micro-electronics, metallurgy, construction building, plastics, lubricants… In parallel, significant progress were made on recycling field (phthalates) and in environmental cleanup (soils, sewage). Adapted equipments are already available.

- Aerogel drying (mineral or organic)

- Cleaning / activation of metallic pieces

- Drying steps in electronic wafers manufacturing

- Metallic powders drying

- Elimination of molding waxes

- Fluorinated liquid polymers fractionation

- Destruction of ultimate wastes with supercritical water

- Micro-electronics (cleaning ang drying)

- Aerogels (fundamental physics, construction buildings, spatial…)

- Cutting tools manufacturing (sintered metals)

- Recycling materials

- Hazardous substances destruction (combat gas)

- Activated carbon regeneration (VOCs treatment)

- Monomers / oligomers elimination (after polymerization step)

- Dying of tissues (polyester) without using water

Our achievements

- All

- Achievements

- Chemistry Pharmacy Petrochemistry

- Cosmetics

- Process engineering