The advantages of using CO2 :

Low critical point: 31°C and 74 bar

Inexpensive, chemically inert, non-toxic, non-flammable, available, with high purity

selective extraction of molecules with pressure and temperature variation

extracts and residues are free of solvents

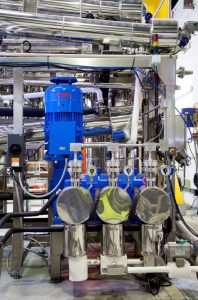

This skid includes :

– a CO2 pump,

– an extractor with a basket,

– a separator,

– a utility network (compressed air, hot and cold water)

– a SCADA system..