ER INGENIERIE, your partner for the design, manufacture and implementation of turnkey special machines and production lines for manufacturing industries:

Manufacturing Industries

Manufacturer of special machines for manufacturing industries

Automated assembly lines

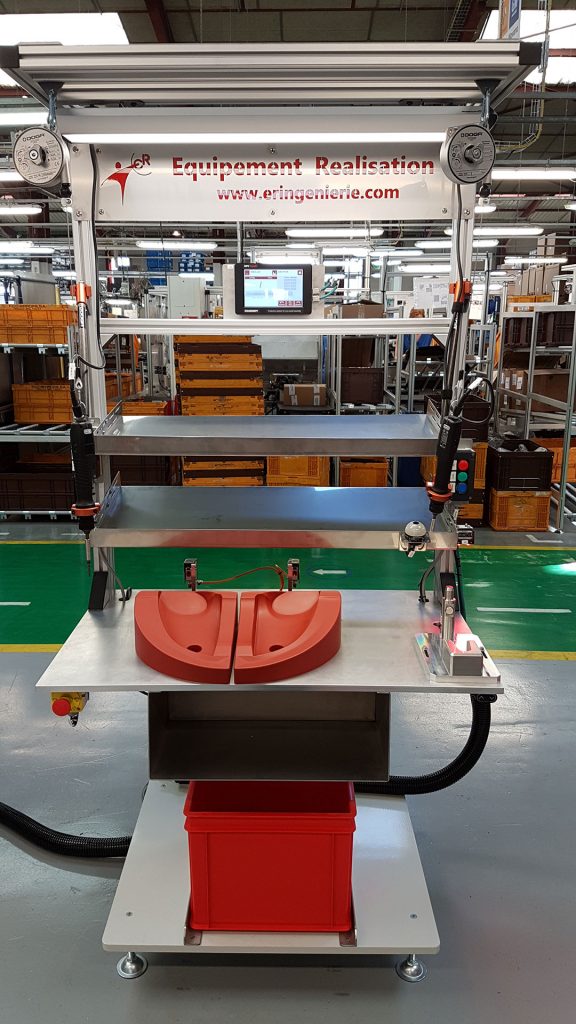

Semi-automatic workstations

Packing and packaging lines

Integration of robots and robot cells

Collaborative robotics

Integration of industrial vision solutions,

Integration of marking solutions,

Integration of automatic screwing solutions,

Integration of crimping and riveting solutions

Integration of vibratory bowl feeders

Testbed

Retrofit of special machines

SPECIAL INDUSTRIAL FOOD PROCESSING MACHINES – INDUSTRIAL ROBOTICS COMPANY

Manufacture and installation of special machines for the food industry: special machine for placing blocks and cardboards on containers, special machine for stacking genoise plates, etc.

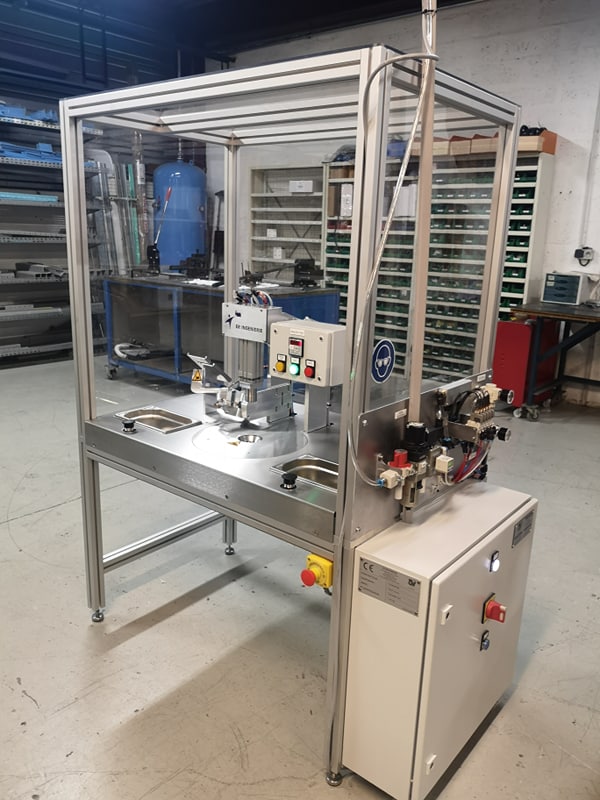

- Special machines

- Engineering

- Electricity

- Automatism

- Information Technology

- Mechanics

- Conveying

- Robotics

- Process piping

- C.I.P

- Water quality monitoring

- Air treatment

- Mechanization

- Robot cells

- Special machine for placing blocks and cardboards on containers

- Special machine for stacking genoise plates

- Filling

- Conveying

- Quality control

- Non-destructive testing

- Cleaning in Place

SPECIAL MACHINES FOR AUTOMATED OPERATIONS

An evolving sector and a driving force for the development and application of new technologies.

- Engineering

- Supply Chain

- Industrial Design

- Flow management

- Mechanics

- Electricity (LV and HV)

- Automatism

- Pneumatics

- Information technology

- Supervision

- Conveying

- Assembling

- Screwing in

- Welding

- Robotics

- Tube expansion

- Electrical control

- Poka-Yoke

- Vision

- Pick and Place

- Regulation

- Packaging

- Sanitation

- Continuous improvement

- Ergonomics

- Compliance with standards

- Maintenance

- Leak test

- Brake caliper assembly line / bellows on rods Expansion tube machine

- Sun visor assembly line

- Bearing assembly on stabilizer bar

- Assembly line of thermal dynamic cabin with Poka-Yoke zone

- Automotive seat assembly line after painting

- Robotic station for primer applying on windows and hinges installing and hanging devices

- Air ducts fitting tools

- Semi-automatic machine for assembling pumps and gas gauges Screwing station Marking station

- Turbo flow station

- Flow and calibration station

- Turbo regulator assembly station

- Screwing station for electric actuator locks

- Assembly and control station of locks Press-fitting station Slam lock station (lock test)

- Control means of thermal motor / sealing / electric / direction of rotation and Poka-Yoke

- Air testbed for water pumps / torque control / sealing / presence of threads check

- Leak test for multi-functional covers oil pumps / water pumps

- In-line tooth tracking machine on torsion bars Measuring station, machining and torsion bars control

- Control station (electrical and vision) of speedometers Vibration control station of speedometers

- Automatic stacking machine on press exit of clutch disc, steel or cast iron sheet

- Assembly machine for oil pumps

DESIGNER OF SPECIAL MACHINES FOR THE GLASS INDUSTRY

We install and manufacture special equipments and process piping. We are also involved in the remachining of machines and the implementation of specific electrical installations.

- Engineering

- Industrial Design

- Electrical installations

- Compliance

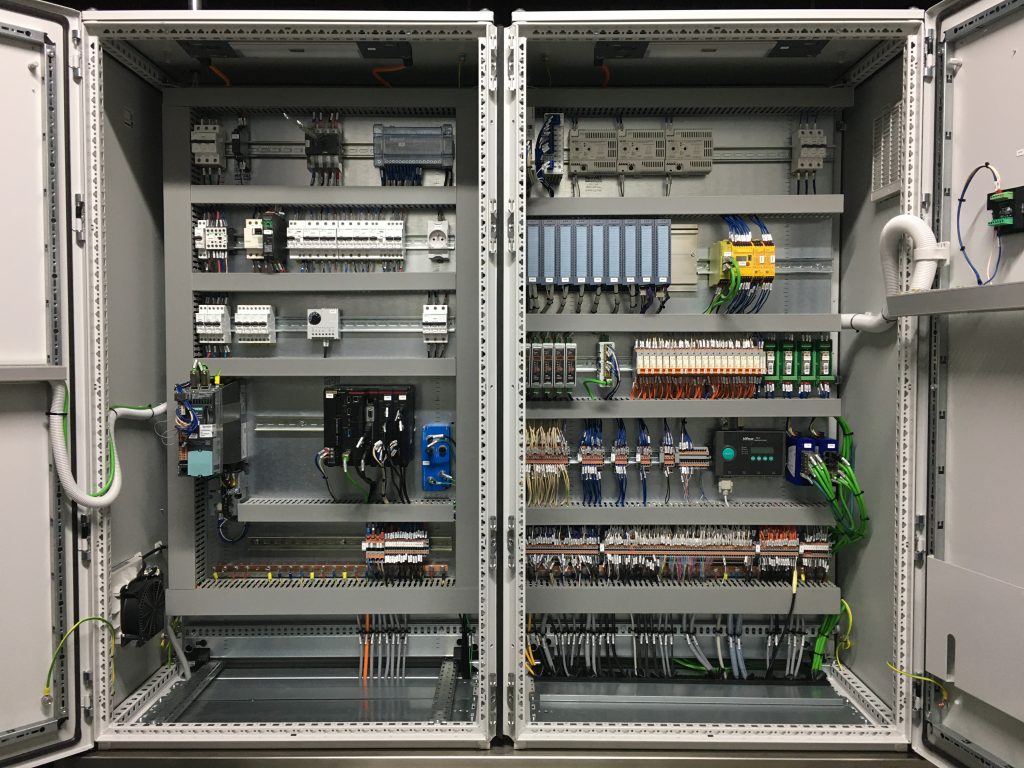

- Wiring of cabinets

- Automatism

- Supervision

- Instrumentation

- Mechanics

- Piping system

- Remachining

- Ergonomics

- Modification of ACS

- Composition weighing

- Dosing station

- ATEX special machines

- Robotization

- Safety and security

- Protection

- X-ray

- Measuring bridge on conveyor / float glass

- Silos and cullet elevators

- Skid ATEX

- Electrical and automation work on arches

- Remachining

- Automation control by sampling

- Design/Modification: automatic control by sampling "ACS" on production lines

- Dosing station cold surface treatment

- Modification of cullet silos and elevator

- Rehabilitation of elevator access

- Manufacturing of cabinets and automation (WIFI transmission) for loading and unloading shuttles of finished products

- Centralized suction of hot surface treatment fumes

- Replacement of cooling pipes "process water"

- Compliance

- Power supply dust removal system for furnace

- Scissor irrigation system

- Composition weighing

- Robotization

- Non-destructive testing

TRAINING OF THE YOUNG AND NOT SO YOUNG

The Industrial experience in the service of education.

- Engineering, electrical studies, mechanical, pneumatic, hydraulic

- Automation and supervision

- Ergonomics

- Robotics and vision

- Turnkey construction of industrial installations and special machines dedicated to the automotive industry, food processing, chemistry - pharmacy, environment, etc.

- Electric, pneumatic and hydraulic benches

- Electrical and leak testbed

- Instrumentation and regulation bench

- Pumping and filtration unit

- Process control

- Simulation bench

- Various pedagogical scale models...

MANUFACTURE OF SPECIAL MACHINES

Studies of specific industrial projects: production, assembly, welding, control, conveying, finishing, etc.

- Engineering

- Industrial Design

- Electrical installations

- Mechanical installations

- Process piping

- Pedagogical scale models

- Special machines

- Special machines

- Retrofit

- Industrial transfer

- Water control

- Air treatment

- Ergonomics

- Pedagogical scale model

- Control console

- Automatic welding machine of platelet rods for quartz lamps

- Control cabinet with PLC

CONTROL AND DETAILED ANALYSIS OF THE MATERIAL. TOMOGRAPHY – INDUSTRIAL DESIGN – 3D METROLOGY – THREE-DIMENSIONAL VISION

X-ray microtomography is used both in production (quality control) and in the prototyping phase, during the development of manufacturing processes or even for reverse engineering.

The improvements made to this technique concern today the quality of three-dimensional reconstructions and the timeliness of information processing. The latest advances now allow real-time controls at resolutions of a tenth of a millimetre.informations. Les dernières avancées permettent désormais des contrôles en temps réel à des résolutions du dixième de millimètre.

- Detection of defects in parts and assemblies

- Tomography

- Line quality control

- Identification of porosity and density variation

- 3D Metrology

- Imaging technology

- Industrial Design

- Three-dimensional vision

- X-ray

- Defect detection or foreign bodies detection

- Assembly and dimensional control

- Reverse Engineering

- 3D Modeling

- Prototyping

- Integration of these means of control in an industrial environment

- Control on platform

ETHANOL WASHING SKID FOR MEDICAL DEVICE, EXTRACTION SKID, ASSEMBLY MACHINE,…

Thanks to the world of science and technologies that are constantly progressing medicine allows and gives us hope to live better and longer.

- Health Engineering

- Special machines

- Robotics

- Vision

- Ergonomics

- Testbed

- Non-destructive testing

- Electricity

- Pneumatics

- Automatism

- Process piping

- Air treatment

- Water control

- Welding machine of drainage bags

- Packaging machine

- Assembly machine

- Control machine

- Process installation

- Leak test

- Non-destructive testing

- SKID extraction

- SKID washing system

Our achievements

- All

- Achievements

- Agri-Food Industry

- Automotive Industry

- Industrial Electricity

- Manufacturing Industries

- Various Industries